Line shaft

Videos

Page

A line shaft is a power-driven rotating shaft for power transmission that was used extensively from the Industrial Revolution until the early 20th century. Prior to the widespread use of electric motors small enough to be connected directly to each piece of machinery, line shafting was used to distribute power from a large central power source to machinery throughout a workshop or an industrial complex. The central power source could be a water wheel, turbine, windmill, animal power or a steam engine. Power was distributed from the shaft to the machinery by a system of belts, pulleys and gears known as millwork.

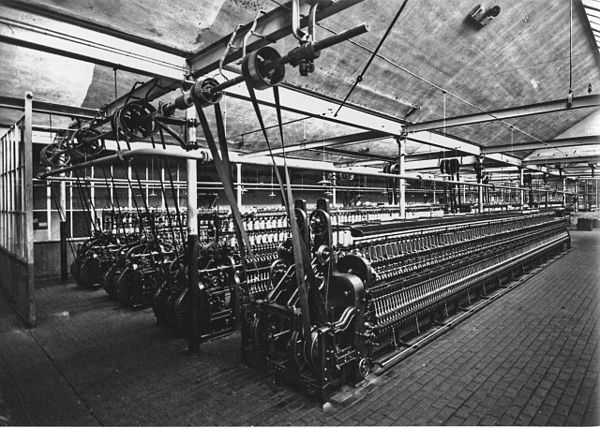

Four wool spinning machines driven by belts from an overhead lineshaft (Leipzig, Germany, circa 1925)

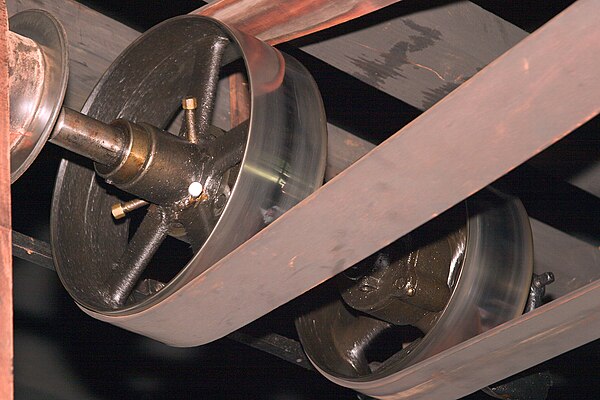

Variable speed belt drive for a lathe. The fixed pulley on the upper shaft is driven at constant speed by a belt from the power source. The loose pulley ('idler') allows the machine to be stopped in isolation – necessary for changing speed. The stepped pulleys (left) provide three drive speeds for the machine tool (not shown), depending on which pair of pulleys is connected by the belt.

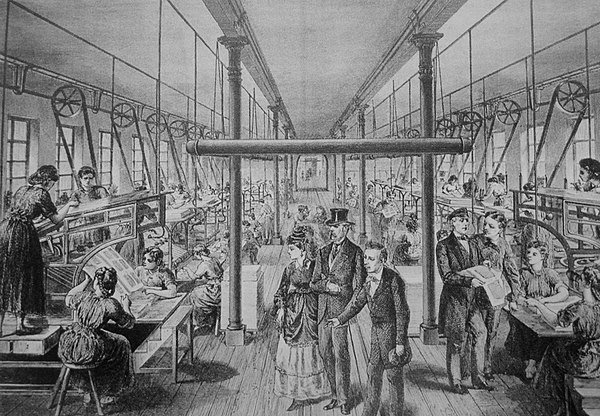

Printing presses in 1870

Jedediah Strutt, North Mill at Belper in 1819, showing vertical shaft leading from the 18 feet (5.5 m) waterwheel, to horizontal drive shafts running the length of each floor

Belt (mechanical)

Videos

Page

A belt is a loop of flexible material used to link two or more rotating shafts mechanically, most often parallel. Belts may be used as a source of motion, to transmit power efficiently or to track relative movement. Belts are looped over pulleys and may have a twist between the pulleys, and the shafts need not be parallel.

Flat belt drive in the machine shop at the Hagley Museum

The drive belt: used to transfer power from the engine's flywheel. Here shown driving a threshing machine.

A small section of a wide flat belt made of layers of leather with the fastener on one end, shown in an exhibit at the Suffolk Mills in Lowell, Massachusetts

A two-stage transmission using spring belts on a toy vehicle