An air compressor is a machine that takes ambient air from the surroundings and discharges it at a higher pressure. It is an application of a gas compressor and a pneumatic device that converts mechanical power into potential energy stored in compressed air, which has many uses. A common application is to compress air into a storage tank, for immediate or later use. When the delivery pressure reaches its set upper limit, the compressor is shut off, or the excess air is released through an overpressure valve. The compressed air is stored in the tank until it is needed. The pressure energy provided by the compressed air can be used for a variety of applications such as pneumatic tools as it is released. When tank pressure reaches its lower limit, the air compressor turns on again and re-pressurizes the tank.

A compressor is different from a pump because it works on a gas, while pumps work on a liquid.

Air compressor supplies air into a nail gun.

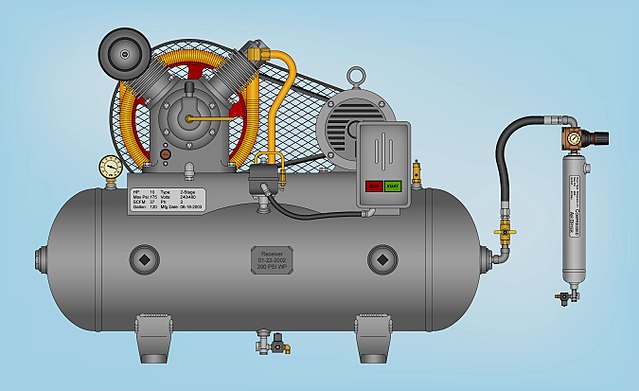

Technical illustration of a two-stage air compressor

Technical illustration of a portable single-stage air compressor

Portable diesel powered air compressor for powering tools, such as jackhammers

Compressed air is air kept under a pressure that is greater than atmospheric pressure.

Compressed air in vehicle tyres and shock absorbers is commonly used for improved traction and reduced vibration. Compressed air is an important medium for transfer of energy in industrial processes, and is used for power tools such as air hammers, drills, wrenches, and others, as well as to atomize paint, to operate air cylinders for automation, and can also be used to propel vehicles. Brakes applied by compressed air made large railway trains safer and more efficient to operate. Compressed air brakes are also found on large highway vehicles.

Air compressor station in a power plant

Technical Illustration of portable single-stage air compressor

Two-stage air compressor assembled on a horizontal tank and equipped with a Joule-Thomson (JT) type refrigerated compressed air dryer