A Bailey bridge is a type of portable, pre-fabricated, truss bridge. It was developed in 1940–1941 by the British for military use during the Second World War and saw extensive use by British, Canadian and American military engineering units. A Bailey bridge has the advantages of requiring no special tools or heavy equipment to assemble. The wood and steel bridge elements were small and light enough to be carried in trucks and lifted into place by hand, without the use of a crane. The bridges were strong enough to carry tanks. Bailey bridges continue to be used extensively in civil engineering construction projects and to provide temporary crossings for pedestrian and vehicle traffic.

Bailey bridge over the Meurthe River, France

The transoms, side-panels and stringers of a Bailey bridge section at the Memorial Pegasus museum in Ranville, Calvados, France, can all be clearly seen

Royal Engineers construct a Bailey bridge in Italy, September 1943. Wood planks are being laid over the stringers to construct the roadbed

Prototype Bailey Bridge at Stanpit Marsh in Dorset

Military engineering is loosely defined as the art, science, and practice of designing and building military works and maintaining lines of military transport and military communications. Military engineers are also responsible for logistics behind military tactics. Modern military engineering differs from civil engineering. In the 20th and 21st centuries, military engineering also includes CBRN defense and other engineering disciplines such as mechanical and electrical engineering techniques.

Military engineer training in Ukraine, 2017

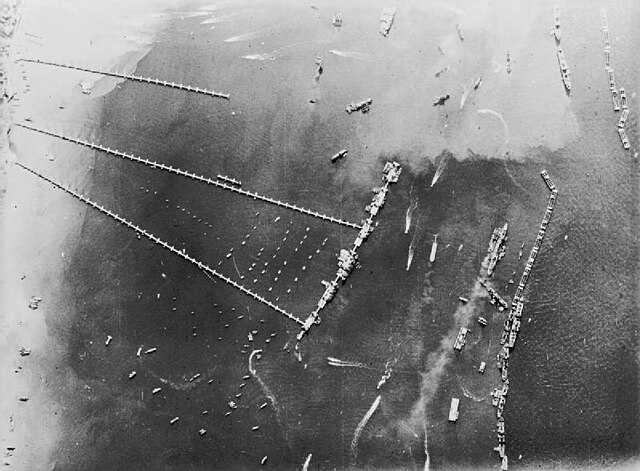

Aerial view of Mulberry harbour "B" (27 October 1944)

US Combat Engineer setting a charge (1944)

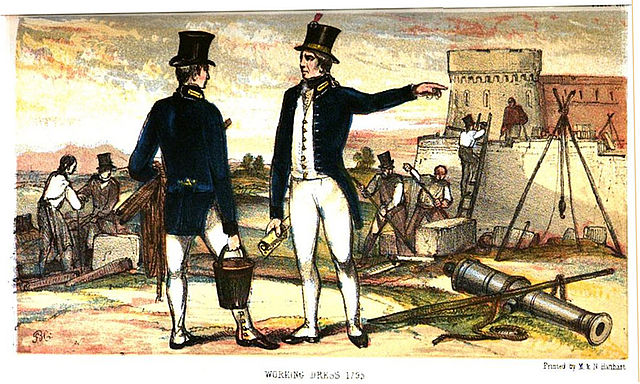

Working dress of the Royal Military Artificers in Gibraltar, 1795