Bihar is a state in Eastern India. It is the third largest state by population, the 12th largest by area, and the 14th largest by GDP in 2021. Bihar borders Uttar Pradesh to its west, Nepal to the north, the northern part of West Bengal to the east, and Jharkhand to the south. Bihar is split by the river Ganges, which flows from west to east. On 15 November 2000, southern Bihar was ceded to form the new state of Jharkhand. Only 11.27% of the population of Bihar lives in urban areas as per a 2020 report. Additionally, almost 58% of Biharis are below the age of 25, giving Bihar the highest proportion of young people of any Indian state. The official language is Hindi, which shares official status alongside that of Urdu. The main native languages are Maithili, Magahi and Bhojpuri. But there are several other languages being spoken at smaller levels.

Image: Mahavir Mandir from Buddha Smriti Park

Image: Buddha Smriti Park

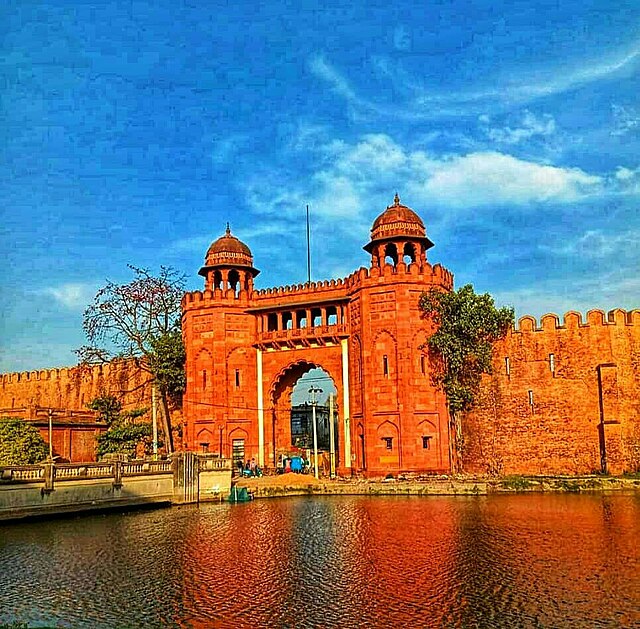

Image: Fort of Darbhanga

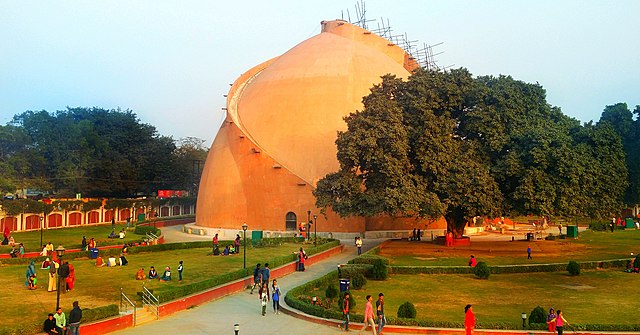

Image: Golghar patna

States and union territories of India

India is a federal union comprising 28 states and 8 union territories, for a total of 36 entities. The states and union territories are further subdivided into districts and smaller administrative divisions.

Administrative divisions of the Indian Empire in 1909

Administrative divisions of the Union of India in 1949