Carburizing, or carburising, is a heat treatment process in which iron or steel absorbs carbon while the metal is heated in the presence of a carbon-bearing material, such as charcoal or carbon monoxide. The intent is to make the metal harder and more wear resistant. Depending on the amount of time and temperature, the affected area can vary in carbon content. Longer carburizing times and higher temperatures typically increase the depth of carbon diffusion. When the iron or steel is cooled rapidly by quenching, the higher carbon content on the outer surface becomes hard due to the transformation from austenite to martensite, while the core remains soft and tough as a ferritic and/or pearlite microstructure.

A modern computerised gas carburising furnace

Heat treating is a group of industrial, thermal and metalworking processes used to alter the physical, and sometimes chemical, properties of a material. The most common application is metallurgical. Heat treatments are also used in the manufacture of many other materials, such as glass. Heat treatment involves the use of heating or chilling, normally to extreme temperatures, to achieve the desired result such as hardening or softening of a material. Heat treatment techniques include annealing, case hardening, precipitation strengthening, tempering, carburizing, normalizing and quenching. Although the term heat treatment applies only to processes where the heating and cooling are done for the specific purpose of altering properties intentionally, heating and cooling often occur incidentally during other manufacturing processes such as hot forming or welding.

Heat treating furnace at 1,800 °F (980 °C)

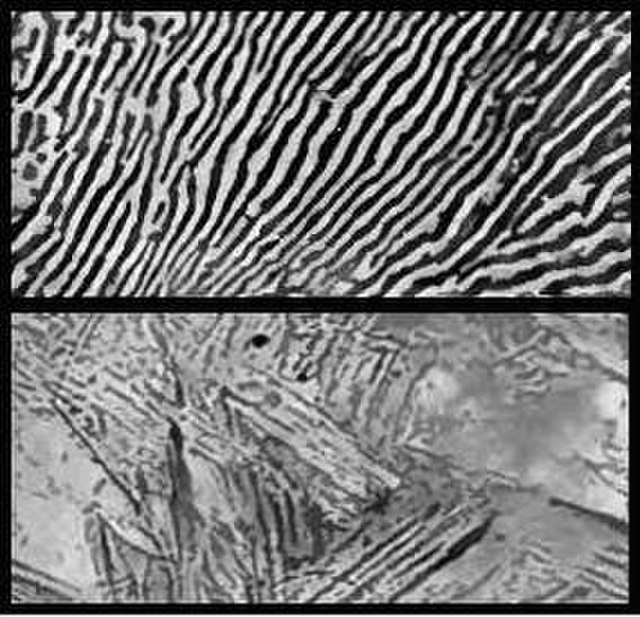

Photomicrographs of steel. Top: In annealed (slowly cooled) steel, the carbon precipitates forming layers of ferrite (iron) and cementite (carbide). Bottom: In quenched (quickly cooled) steel, the carbon remains trapped in the iron, creating great internal stresses in the needle or plate-like grains.

Hypereutectoid steel

Steel castings after undergoing 12-hour 1,200 °C (2,190 °F) heat treatment.