A connecting rod, also called a 'con rod', is the part of a piston engine which connects the piston to the crankshaft. Together with the crank, the connecting rod converts the reciprocating motion of the piston into the rotation of the crankshaft. The connecting rod is required to transmit the compressive and tensile forces from the piston. In its most common form, in an internal combustion engine, it allows pivoting on the piston end and rotation on the shaft end.

Typical design of automobile engine connecting rod

Typical aluminium rod (left), oil drip rod (centre), steel rod (right)

Beam engine with twin connecting rods (almost vertical) between the horizontal beam and the flywheel

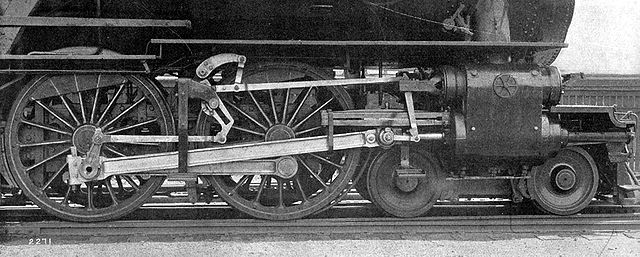

Steam locomotive connecting rod (between the piston and the rear wheel; the largest rod visible)

A reciprocating engine, also often known as a piston engine, is typically a heat engine that uses one or more reciprocating pistons to convert high temperature and high pressure into a rotating motion. This article describes the common features of all types. The main types are: the internal combustion engine, used extensively in motor vehicles; the steam engine, the mainstay of the Industrial Revolution; and the Stirling engine for niche applications. Internal combustion engines are further classified in two ways: either a spark-ignition (SI) engine, where the spark plug initiates the combustion; or a compression-ignition (CI) engine, where the air within the cylinder is compressed, thus heating it, so that the heated air ignites fuel that is injected then or earlier.

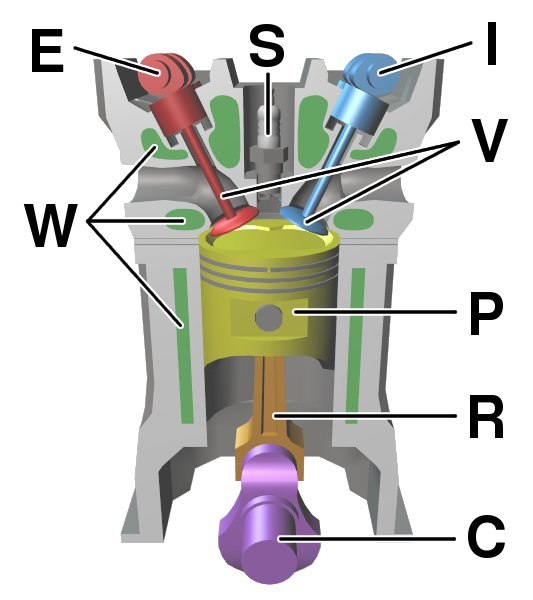

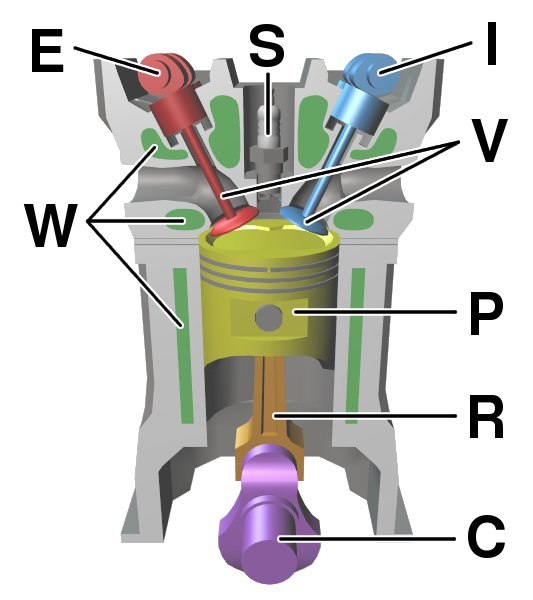

Internal combustion piston engine Components of a typical, four-stroke cycle, internal combustion, gasoline piston engine. C. Crankshaft E. Exhaust camshaft I. Intake camshaft P. Piston R. Connecting rod S. Spark plug W. Water jacket for coolant flow V. Valves

Ray-traced image of a piston engine