Differential heat treatment

Differential heat treatment is a technique used during heat treating of steel to harden or soften certain areas of an object, creating a difference in hardness between these areas. There are many techniques for creating a difference in properties, but most can be defined as either differential hardening or differential tempering. These were common heat treatment techniques used historically in Europe and Asia, with possibly the most widely known example being from Japanese swordsmithing. Some modern varieties were developed in the twentieth century as metallurgical knowledge and technology rapidly increased.

A differentially hardened sword, showing the hardened edge as the whiter portion of the blade.

Diagram of a cross section of a katana, showing the typical arrangement of the harder and softer zones.

The curving of a katana during quenching first begins with a downward bend as the edge cools, followed by an upward bend as the rest of the sword cools.

A katana, shown at a long angle to reveal the nioi, which is the bright line following the hamon. The inset shows a close up of the nioi, which appears as the speckled area between the bright hardened edge and the darker soft zone. The wood-grain appearance is from the folding techniques used during forging.

Heat treating is a group of industrial, thermal and metalworking processes used to alter the physical, and sometimes chemical, properties of a material. The most common application is metallurgical. Heat treatments are also used in the manufacture of many other materials, such as glass. Heat treatment involves the use of heating or chilling, normally to extreme temperatures, to achieve the desired result such as hardening or softening of a material. Heat treatment techniques include annealing, case hardening, precipitation strengthening, tempering, carburizing, normalizing and quenching. Although the term heat treatment applies only to processes where the heating and cooling are done for the specific purpose of altering properties intentionally, heating and cooling often occur incidentally during other manufacturing processes such as hot forming or welding.

Heat treating furnace at 1,800 °F (980 °C)

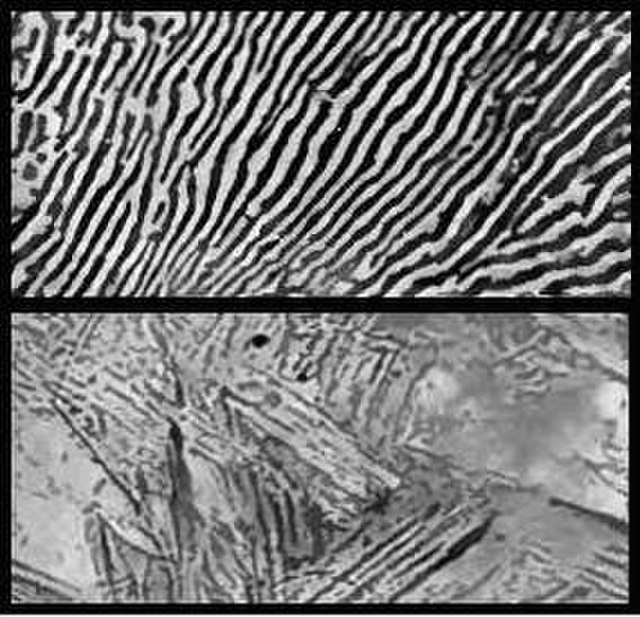

Photomicrographs of steel. Top: In annealed (slowly cooled) steel, the carbon precipitates forming layers of ferrite (iron) and cementite (carbide). Bottom: In quenched (quickly cooled) steel, the carbon remains trapped in the iron, creating great internal stresses in the needle or plate-like grains.

Hypereutectoid steel

Steel castings after undergoing 12-hour 1,200 °C (2,190 °F) heat treatment.