Distributed control system

A distributed control system (DCS) is a computerized control system for a process or plant usually with many control loops, in which autonomous controllers are distributed throughout the system, but there is no central operator supervisory control. This is in contrast to systems that use centralized controllers; either discrete controllers located at a central control room or within a central computer. The DCS concept increases reliability and reduces installation costs by localizing control functions near the process plant, with remote monitoring and supervision.

A pre-DCS era central control room. Whilst the controls are centralised in one place, they are still discrete and not integrated into one system.

A DCS control room where plant information and controls are displayed on computer graphics screens. The operators are seated as they can view and control any part of the process from their screens, whilst retaining a plant overview.

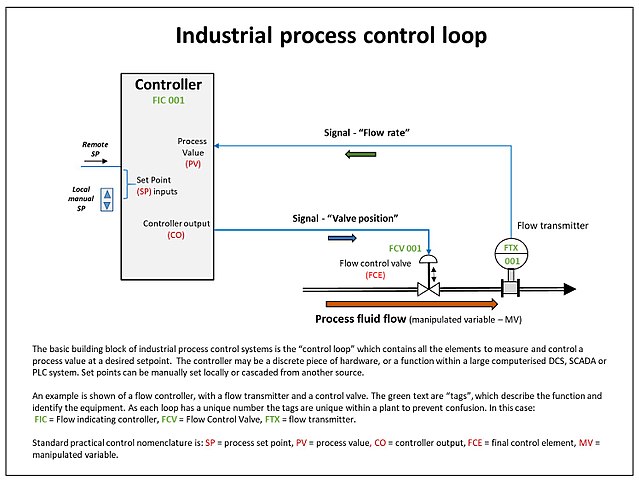

A control system manages, commands, directs, or regulates the behavior of other devices or systems using control loops. It can range from a single home heating controller using a thermostat controlling a domestic boiler to large industrial control systems which are used for controlling processes or machines. The control systems are designed via control engineering process.

The centrifugal governor is an early proportional control mechanism.

An electromechanical timer, normally used for open-loop control based purely on a timing sequence, with no feedback from the process

Example of a single industrial control loop; showing continuously modulated control of process flow.

A DCS control room where large screens display plant information. The operators can view and control any part of the process from their computer screens, whilst retaining a plant overview on the larger screens.