Engine balance refers to how the inertial forces produced by moving parts in an internal combustion engine or steam engine are neutralised with counterweights and balance shafts, to prevent unpleasant and potentially damaging vibration. The strongest inertial forces occur at crankshaft speed and balance is mandatory, while forces at twice crankshaft speed can become significant in some cases.

Harmonic damper for a 1937 Pontiac engine

Balance shaft system: 1922 design by the Lanchester Motor Company

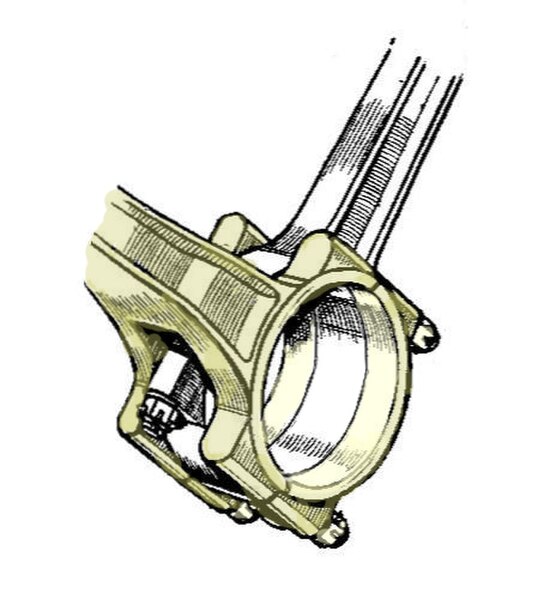

Fork-and-blade connecting rods

BMW R50/2 flat-twin engine viewed from above, showing the offset between the left & right cylinders

Balance shafts are used in piston engines to reduce vibration by cancelling out unbalanced dynamic forces. The counter balance shafts have eccentric weights and rotate in opposite direction to each other, which generates a net vertical force.

Balance shaft in Ford Taunus V4 engine.

Lanchester's vertical force balancer. The eccentric masses are labelled "C" and "D".

Valve timing gears on a Ford Taunus V4 engine. The balance shaft runs off the small gear on the left (the large gear is for the camshaft, causing it to rotate at half the speed of the crankshaft).