Ethan Green Hawke is an American actor, author and film director. He made his film debut in Explorers (1985), before making a breakthrough performance in Dead Poets Society (1989). Hawke starred alongside Julie Delpy in Richard Linklater's Before trilogy from 1995 to 2013. Hawke received two nominations for the Academy Award for Best Supporting Actor for Training Day (2001) and Boyhood (2014) and two for Best Adapted Screenplay for co-writing Before Sunset (2004) and Before Midnight (2013). Other notable roles include in Reality Bites (1994), Gattaca (1997), Great Expectations (1998), Before the Devil Knows You're Dead (2007), Maggie's Plan (2015), First Reformed (2017), The Black Phone (2021) and The Northman (2022).

Hawke at the 2018 Montclair Film Festival

Hawke at the premiere of The Hottest State in Austin, Texas, September 2007

Hawke at the 2007 Toronto International Film Festival

Hawke at the premiere of Before Midnight in Berlin, Germany, February 2013

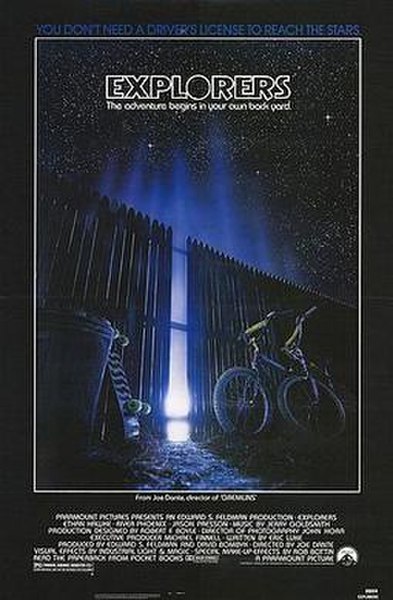

Explorers is a 1985 American science fantasy film written by Eric Luke and directed by Joe Dante. The film stars Ethan Hawke and River Phoenix, both in their film debuts, and Jason Presson as young teenage boys who build a spacecraft to explore outer space. The special effects were produced by Industrial Light & Magic, with make-up effects by Rob Bottin.

Theatrical release poster