The FIFA World Cup is a solid gold trophy that is awarded to the winners of the FIFA World Cup association football tournament. Since the advent of the World Cup in 1930, two different trophies have been used: the Jules Rimet Trophy from 1930 to 1970 and thereafter the FIFA World Cup Trophy from 1974 to the present day. The production cost of the current trophy is estimated at $242,700.

FIFA World Cup Trophy

Jules Rimet Trophy replica on display in the English National Football Museum. The original was stolen from Brazil in 1983 and has never been recovered

Jules Rimet presents the World Cup trophy to Raúl Jude, president of the Uruguayan Football Association, winners of the inaugural 1930 World Cup. This trophy was renamed for Rimet in 1946

Queen Elizabeth II presenting the Jules Rimet trophy to 1966 World Cup winning England captain Bobby Moore

A trophy is a tangible, durable reminder of a specific achievement, serving as recognition or evidence of merit. Trophies are most commonly awarded for sporting events, ranging from youth sports to professional level athletics. Additionally, trophies are presented for achievements in Academic, Arts and Entertainment, Business, Military, Professional awards, Community Service, Hunting, and Environmental accomplishments. In many contexts, especially in sports, medals are often given out either as the trophy or along with more traditional trophies.

The European Champion Clubs' Cup held here by Johan Cruyff in 1972, is awarded to the winners of the UEFA Champions League

Trophy for the 1934 Melbourne Cup. The trophy is an example of a loving cup-styled trophy, with three handles attached to the bowl.

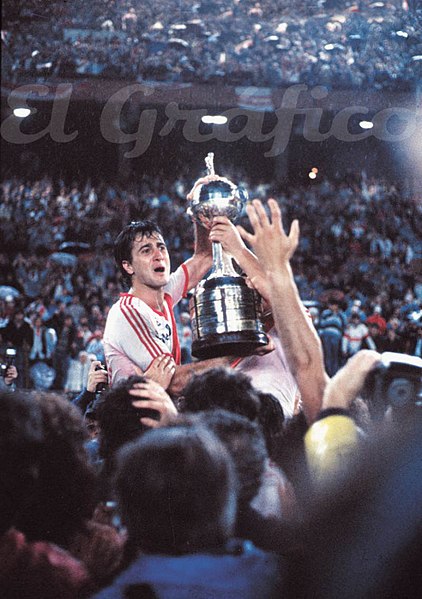

Norberto Alonso with the Copa Libertadores Trophy. The trophy awarded to the champions of Copa Libertadores

Several awards for a Scrabble tournament in Benin