Flow measurement is the quantification of bulk fluid movement. Flow can be measured using devices called flowmeters in various ways. The common types of flowmeters with industrial applications are listed below:Obstruction type

Inferential

Electromagnetic

Positive-displacement flowmeters, which accumulate a fixed volume of fluid and then count the number of times the volume is filled to measure flow.

Fluid dynamic

Anemometer

Ultrasonic flow meter

Mass flow meter.

A positive displacement flowmeter of the oval gear type. Fluid forces the meshed gears to rotate; each rotation corresponds to a fixed volume of fluid. Counting the revolutions totalizes volume, and the rate is proportional to flow.

The paddle wheel assembly generates a flow reading from the fluid flowing through the pipe instigating the spinning of the paddlewheel. Magnets in the paddle spin past the sensor. The electrical pulses produced are proportional to the rate of flow.

A propeller-type current meter as used for hydroelectric turbine testing

8-inch (203 mm) V-cone flowmeter shown with ANSI 300# (21 bar; 2.1 MPa) raised face weld neck flanges

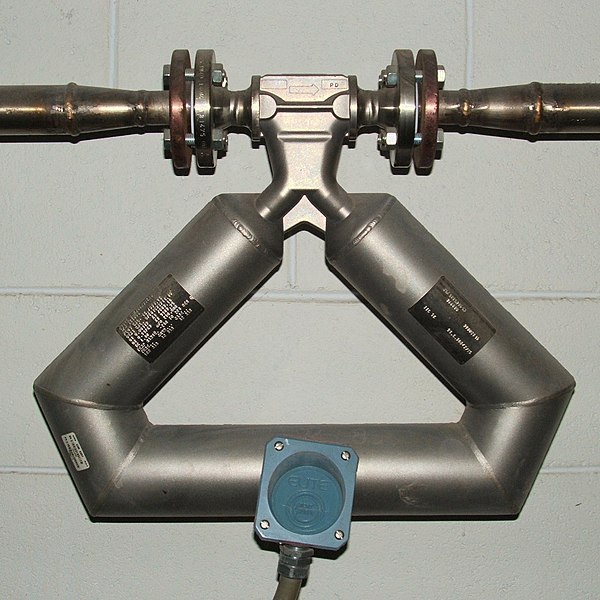

A mass flow meter, also known as an inertial flow meter, is a device that measures mass flow rate of a fluid traveling through a tube. The mass flow rate is the mass of the fluid traveling past a fixed point per unit time.

A mass flow meter of the Coriolis type