Laser cutting is a technology that uses a laser to vaporize materials, resulting in a cut edge. While typically used for industrial manufacturing applications, it is now used by schools, small businesses, architecture, and hobbyists. Laser cutting works by directing the output of a high-power laser most commonly through optics. The laser optics and CNC are used to direct the laser beam to the material. A commercial laser for cutting materials uses a motion control system to follow a CNC or G-code of the pattern to be cut onto the material. The focused laser beam is directed at the material, which then either melts, burns, vaporizes away, or is blown away by a jet of gas, leaving an edge with a high-quality surface finish.

Diagram of a laser cutter

Industrial laser cutting of steel with cutting instructions programmed through the CNC interface

4000 watt CO2 laser cutter

Dual-pallet flying optics laser

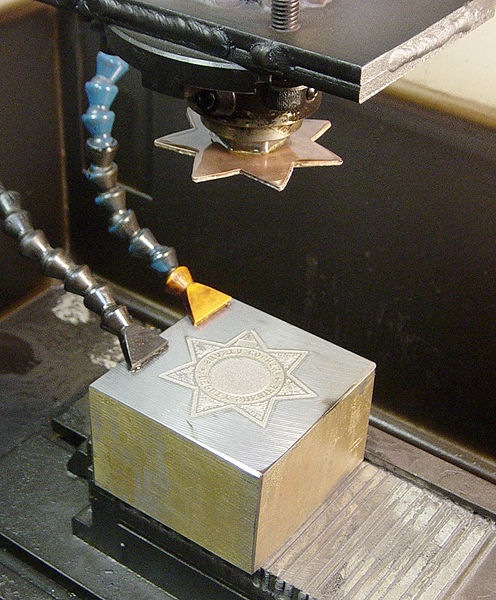

In machining, numerical control, also called computer numerical control (CNC), is the automated control of tools by means of a computer. It is used to operate tools such as drills, lathes, mills, grinders, routers and 3D printers. CNC transforms a piece of material into a specified shape by following coded programmed instructions and without a manual operator directly controlling the machining operation.

A CNC machine that operates on wood

CNC machines typically use some kind of coolant, typically a water-miscible oil, to keep the tool and parts from getting hot.

Sinker EDM. Electrolyte solution saturates the workpiece, and voltage is applied between the sinker, top, and workpiece, bottom.

Waterjet cutting machine