Machining is a manufacturing process where a desired shape or part is created using the controlled removal of material, most often metal, from a larger piece of raw material by cutting. Machining is a form of subtractive manufacturing, which utilizes machine tools, in contrast to additive manufacturing, which uses controlled addition of material.

CNC machine pouring water to keep the tool and parts from getting hot

A "numerical controlled machining cell machinist" monitors a B-1B aircraft part being manufactured.

A Cincinnati shaper with boring bar attached to the clapper box.

Making a shipboard manhole cover in the machine shop of the aircraft carrier USS John C. Stennis.

A machine tool is a machine for handling or machining metal or other rigid materials, usually by cutting, boring, grinding, shearing, or other forms of deformations. Machine tools employ some sort of tool that does the cutting or shaping. All machine tools have some means of constraining the workpiece and provide a guided movement of the parts of the machine. Thus, the relative movement between the workpiece and the cutting tool is controlled or constrained by the machine to at least some extent, rather than being entirely "offhand" or "freehand". It is a power-driven metal cutting machine which assists in managing the needed relative motion between cutting tool and the job that changes the size and shape of the job material.

A metal lathe is an example of a machine tool

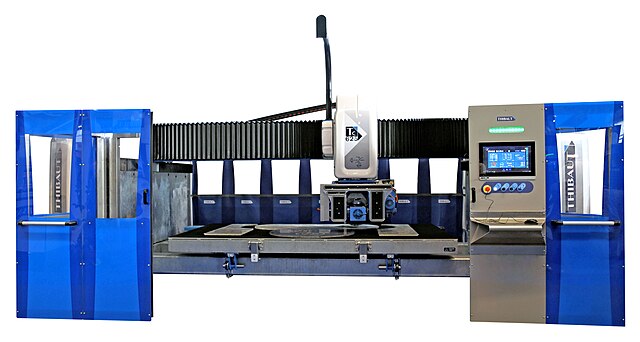

5 axis bridge saw