Nitrocellulose is a highly flammable compound formed by nitrating cellulose through exposure to a mixture of nitric acid and sulfuric acid. One of its first major uses was as guncotton, a replacement for gunpowder as propellant in firearms. It was also used to replace gunpowder as a low-order explosive in mining and other applications. In the form of collodion it was also a critical component in an early photographic emulsion, the use of which revolutionized photography in the 1860s.

Nitrocellulose

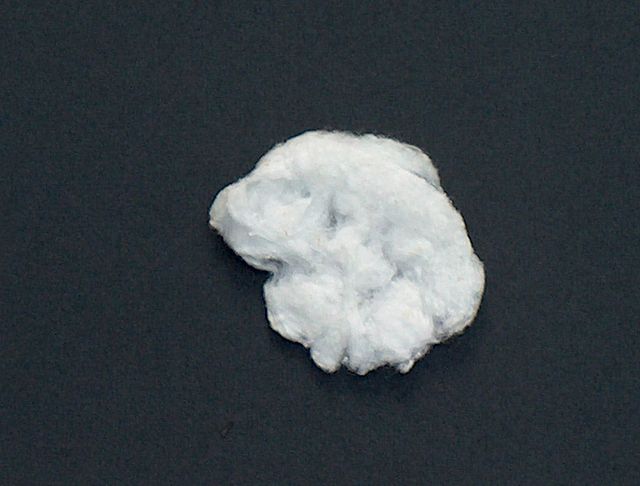

Pure nitrocellulose

Jam tin grenades were made in World War I using gun cotton

Nitrocellulose film on a light box, showing deterioration, from Library and Archives Canada collection

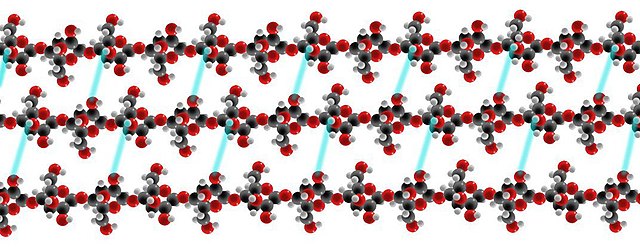

Cellulose is an organic compound with the formula (C6H10O5)n, a polysaccharide consisting of a linear chain of several hundred to many thousands of β(1→4) linked D-glucose units. Cellulose is an important structural component of the primary cell wall of green plants, many forms of algae and the oomycetes. Some species of bacteria secrete it to form biofilms. Cellulose is the most abundant organic polymer on Earth. The cellulose content of cotton fiber is 90%, that of wood is 40–50%, and that of dried hemp is approximately 57%.

Cellulose under a microscope.

A triple strand of cellulose showing the hydrogen bonds (cyan lines) between glucose strands

Cotton fibres represent the purest natural form of cellulose, containing more than 90% of this polysaccharide.