Pope Anacletus, also known as Cletus, was the bishop of Rome, following Peter, and Linus. Anacletus served between c. AD 79 and his death, c. AD 92. Cletus was a Roman who, during his tenure as pope, ordained a number of priests and is traditionally credited with setting up about twenty-five parishes in Rome. Although the precise dates of his pontificate are uncertain, he "...died a martyr, perhaps about 91". Cletus is mentioned in the Roman Canon of the mass; his feast day is April 26.

16th century painting of Anacletus, in the I Gesuiti, Venice, by Palma il Giovane, with anachronistic papal tiara

Statue of Pope Anacletus, from Church of San Cleto, in Rome

The pope, also known as the supreme pontiff, Roman pontiff or sovereign pontiff, is the bishop of Rome, visible head of the worldwide Catholic Church, and has also served as the head of state or sovereign of the Papal States and later the Vatican City State since the eighth century. From a Catholic viewpoint, the primacy of the bishop of Rome is largely derived from his role as the apostolic successor to Saint Peter, to whom primacy was conferred by Jesus, who gave Peter the Keys of Heaven and the powers of "binding and loosing", naming him as the "rock" upon which the Church would be built. The current pope is Francis, who was elected on 13 March 2013.

Pope Francis in 2021

Gregory the Great (c. 540–604), in a painting by Carlo Saraceni, c. 1610, Rome.

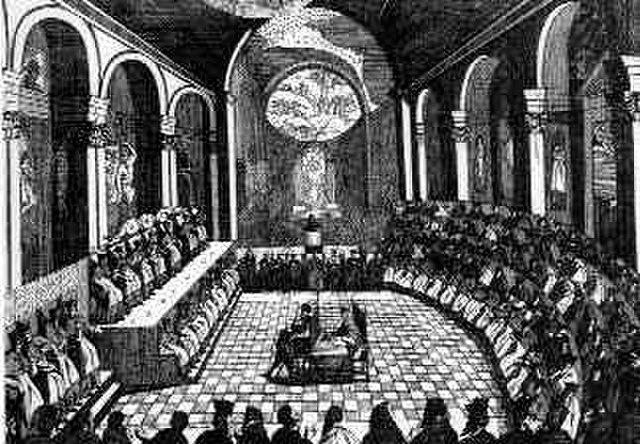

As part of the Catholic Reformation, Pope Paul III (1534–1549) initiated the Council of Trent (1545–1563), which established the triumph of the papacy over those who sought to reconcile with Protestants or oppose papal claims.

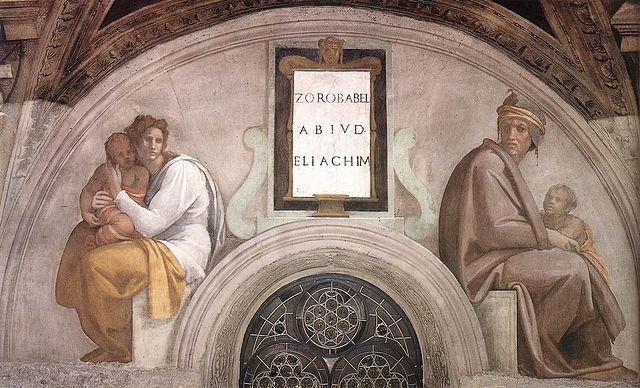

A fresco of Eliakim in Sistine Chapel, Vatican City