The San Antonio Spurs are an American professional basketball team based in San Antonio. The Spurs compete in the National Basketball Association (NBA) as a member of the Southwest Division of the Western Conference. The team plays its home games at Frost Bank Center in San Antonio.

The team's name derives from a spur, a metal tool designed to be worn on the heels of cowboy boots for the purpose of controlling a horse's movement and direction.

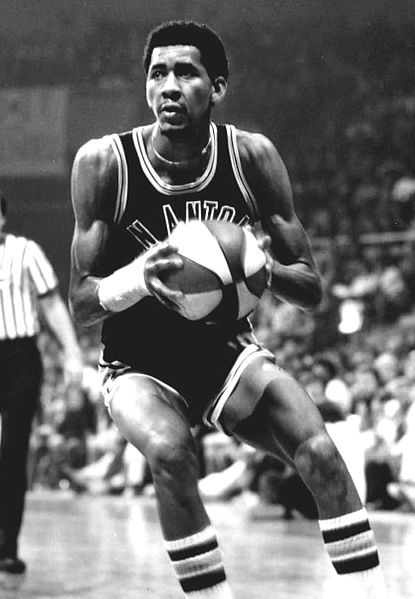

George Gervin served as a foundation piece for the Spurs for almost a decade between 1976 and 1985

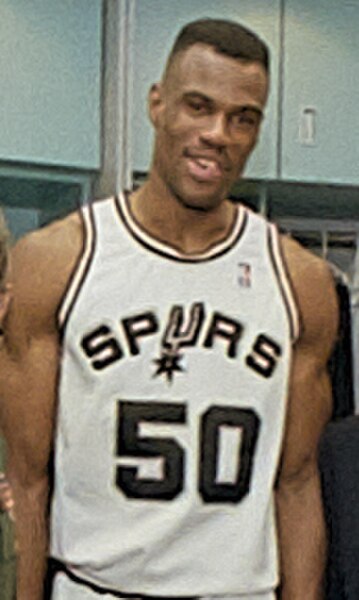

David Robinson was named NBA Most Valuable Player in 1995 and later helped the Spurs win its first NBA championship in 1999.

The Alamodome, home to the Spurs from 1993 to 2002

San Antonio, officially the City of San Antonio, is a city in the U.S. state of Texas and the most populous city in Greater San Antonio, the third-largest metropolitan area in Texas and the 24th-largest metropolitan area in the United States at 2.6 million people in 2020. It is the most populous city in and seat of Bexar County. The city is the seventh-most populous in the United States, the second-largest in the Southern United States, and the second-most populous in Texas after Houston.

Image: Downtown San Antonio view from The Tower of the Americas

Image: Alamo Mission San Antonio at Night

Image: San Antonio Riverwalk with boat tour view

Image: San Antonio, Texas (2018) 057