Tempering is a process of heat treating, which is used to increase the toughness of iron-based alloys. Tempering is usually performed after hardening, to reduce some of the excess hardness, and is done by heating the metal to some temperature below the critical point for a certain period of time, then allowing it to cool in still air. The exact temperature determines the amount of hardness removed, and depends on both the specific composition of the alloy and on the desired properties in the finished product. For instance, very hard tools are often tempered at low temperatures, while springs are tempered at much higher temperatures.

Differentially tempered steel. The various colors produced indicate the temperature the steel was heated to. Light straw indicates 204 °C (399 °F) and light blue indicates 337 °C (639 °F).

Photomicrograph of martensite, a very hard microstructure formed when steel is quenched. Tempering reduces the hardness in the martensite by transforming it into various forms of tempered martensite.

Pieces of through-tempered steel flatbar. The first one, on the left, is normalized steel. The second is quenched, untempered martensite. The remaining pieces have been tempered in an oven to their corresponding temperature, for an hour each. "Tempering standards" like these are sometimes used by blacksmiths for comparison, ensuring that the work is tempered to the proper color.

A differentially tempered sword. The center is tempered to a springy hardness while the edges are tempered slightly harder than a hammer.

Heat treating is a group of industrial, thermal and metalworking processes used to alter the physical, and sometimes chemical, properties of a material. The most common application is metallurgical. Heat treatments are also used in the manufacture of many other materials, such as glass. Heat treatment involves the use of heating or chilling, normally to extreme temperatures, to achieve the desired result such as hardening or softening of a material. Heat treatment techniques include annealing, case hardening, precipitation strengthening, tempering, carburizing, normalizing and quenching. Although the term heat treatment applies only to processes where the heating and cooling are done for the specific purpose of altering properties intentionally, heating and cooling often occur incidentally during other manufacturing processes such as hot forming or welding.

Heat treating furnace at 1,800 °F (980 °C)

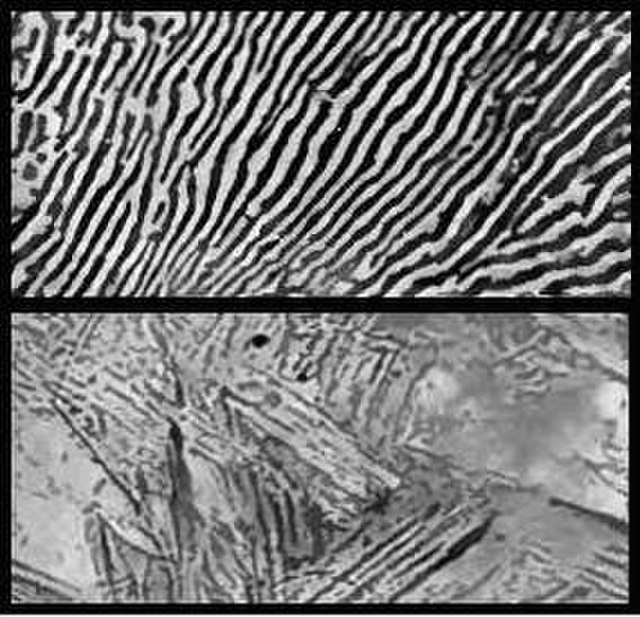

Photomicrographs of steel. Top: In annealed (slowly cooled) steel, the carbon precipitates forming layers of ferrite (iron) and cementite (carbide). Bottom: In quenched (quickly cooled) steel, the carbon remains trapped in the iron, creating great internal stresses in the needle or plate-like grains.

Hypereutectoid steel

Steel castings after undergoing 12-hour 1,200 °C (2,190 °F) heat treatment.