Tiberias is an Israeli city on the western shore of the Sea of Galilee. A major Jewish center during Late Antiquity, it has been considered since the 16th century one of Judaism's Four Holy Cities, along with Jerusalem, Hebron, and Safed. In 2022, it had a population of 48,472.

Tiberias

The Roman-Byzantine southern city gate

Remains of Crusader fortress gate with ancient lintel in secondary use

Remains of Roman theatre

Hebrew is a Northwest Semitic language within the Afroasiatic language family. A regional dialect of the Canaanite languages, it was natively spoken by the Israelites and remained in regular use as a first language until after 200 CE and as the liturgical language of Judaism and Samaritanism. The language was revived as a spoken language in the 19th century, and is the only successful large-scale example of linguistic revival. It is the only Canaanite language, as well as one of only two Northwest Semitic languages, with the other being Aramaic, still spoken today.

Portion of the Isaiah Scroll, a second-century BCE manuscript of the Biblical Book of Isaiah and one of the best-preserved of the Dead Sea Scrolls.

The word IVRIT ("Hebrew") written in modern Hebrew language (top) and in Paleo-Hebrew alphabet (bottom)

A silver matchbox holder with inscription in Hebrew

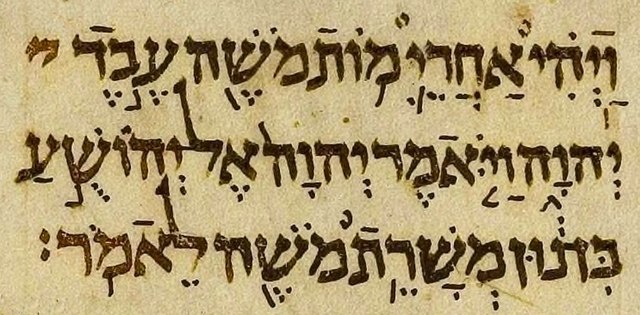

Aleppo Codex: 10th century Hebrew Bible with Masoretic pointing (Joshua 1:1).