In electrical engineering, a transformer is a passive component that transfers electrical energy from one electrical circuit to another circuit, or multiple circuits. A varying current in any coil of the transformer produces a varying magnetic flux in the transformer's core, which induces a varying electromotive force (EMF) across any other coils wound around the same core. Electrical energy can be transferred between separate coils without a metallic (conductive) connection between the two circuits. Faraday's law of induction, discovered in 1831, describes the induced voltage effect in any coil due to a changing magnetic flux encircled by the coil.

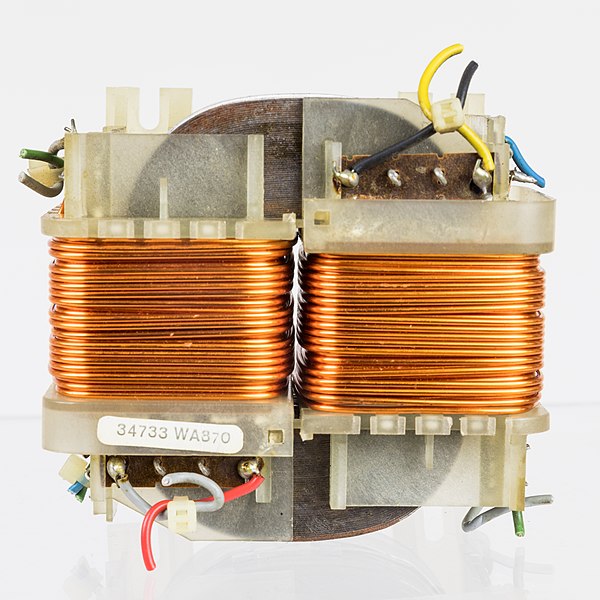

An O-core transformer consisting of two coils of copper wire wrapped around a magnetic core

Instrument transformer, with polarity dot and X1 markings on low-voltage ("LV") side terminal

Core form = core type; shell form = shell type

Shell type transformer with laminated core showing edges of laminations at the top of the photo

Passivity is a property of engineering systems, most commonly encountered in analog electronics and control systems. Typically, analog designers use passivity to refer to incrementally passive components and systems, which are incapable of power gain. In contrast, control systems engineers will use passivity to refer to thermodynamically passive ones, which consume, but do not produce, energy. As such, without context or a qualifier, the term passive is ambiguous.

Television signal splitter consisting of a passive high-pass filter (left) and a passive low-pass filter (right). The antenna is connected to the screw terminals to the left of center.