The Wankel engine is a type of internal combustion engine using an eccentric rotary design to convert pressure into rotating motion. The concept was proven by German engineer Felix Wankel, followed by a commercially feasible engine designed by German engineer Hanns-Dieter Paschke. The Wankel engine's rotor, which creates the turning motion, is similar in shape to a Reuleaux triangle, with the sides having less curvature. The rotor spins inside a figure-eight-like epitrochoidal housing around a fixed-toothed gearing. The midpoint of the rotor moves in a circle around the output shaft, rotating the shaft via a cam.

Figure 2. The first DKM Wankel engine designed by Felix Wankel, the DKM 54 (Drehkolbenmotor), at the Deutsches Museum in Bonn

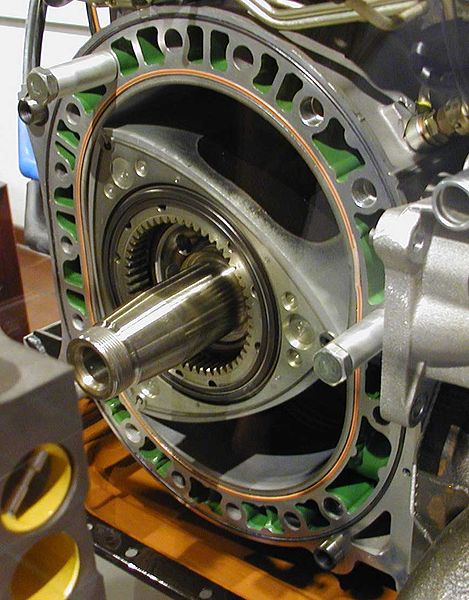

Figure 3. A Wankel engine with its rotor and geared output shaft

Figure 5. The first KKM Wankel Engine based on a design by Hanns-Dieter Paschke, the NSU KKM 57P (Kreiskolbenmotor), at Autovision und Forum

Figure 6. First production Wankel engine; installed in an NSU Spider

Internal combustion engine

An internal combustion engine is a heat engine in which the combustion of a fuel occurs with an oxidizer in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal combustion engine, the expansion of the high-temperature and high-pressure gases produced by combustion applies direct force to some component of the engine. The force is typically applied to pistons, turbine blades, a rotor, or a nozzle. This force moves the component over a distance, transforming chemical energy into kinetic energy which is used to propel, move or power whatever the engine is attached to.

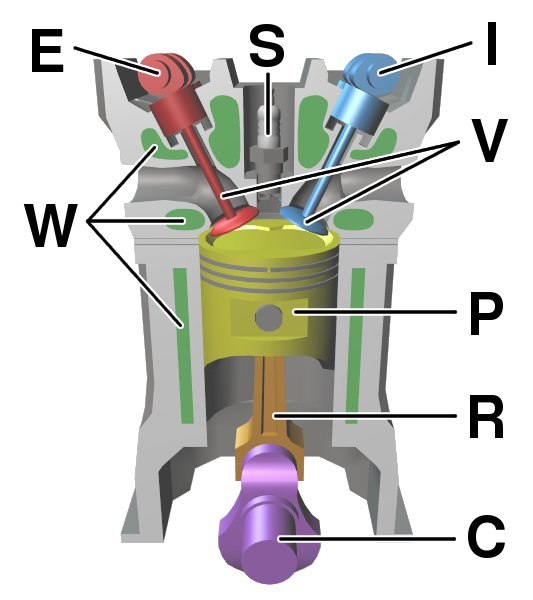

Diagram of a cylinder as found in an overhead cam 4-stroke gasoline engine: C – crankshaft E – exhaust camshaft I – inlet camshaft P – piston R – connecting rod S – spark plug V – valves. red: exhaust, blue: intake. W – cooling water jacket gray structure – engine block

Reciprocating engine of a car

Diesel generator for backup power

Bare cylinder block of a V8 engine