Metal whiskering is a phenomenon that occurs in electrical devices when metals form long whisker-like projections over time. Tin whiskers were noticed and documented in the vacuum tube era of electronics early in the 20th century in equipment that used pure, or almost pure, tin solder in their production. It was noticed that small metal hairs or tendrils grew between metal solder pads, causing short circuits. Metal whiskers form in the presence of compressive stress. Germanium, zinc, cadmium, and even lead whiskers have been documented. Many techniques are used to mitigate the problem, including changes to the annealing process, the addition of elements like copper and nickel, and the inclusion of conformal coatings. Traditionally, lead has been added to slow down whisker growth in tin-based solders.

Silver whiskers growing out of surface-mount resistors

Microscopic view of tin used to solder electronic components, showing a whisker

Several mm long zinc whiskers on zinc-coated steel

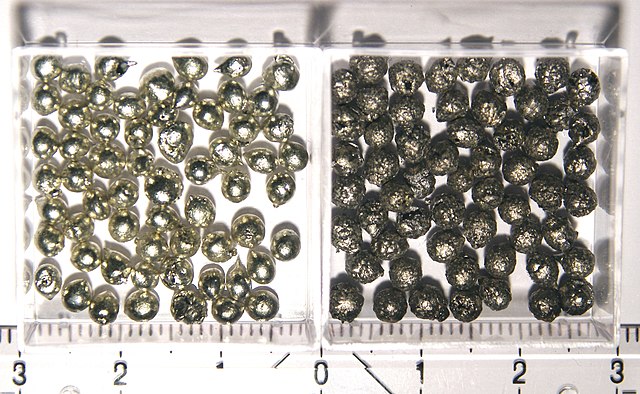

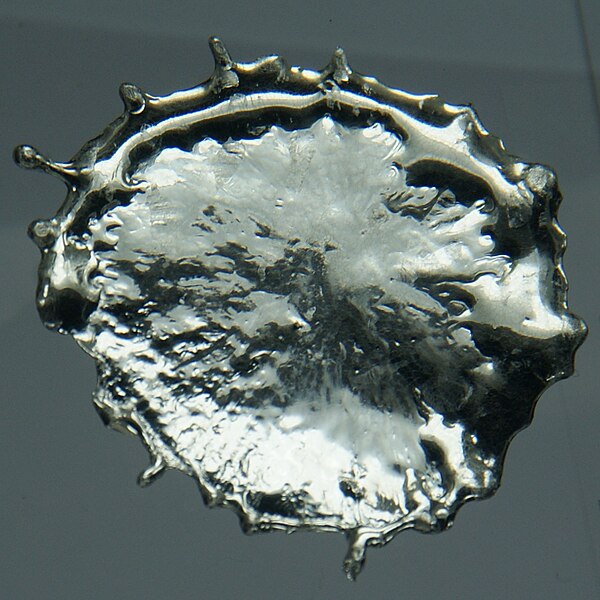

Tin is a chemical element; it has symbol Sn and atomic number 50. A silvery-colored metal, tin is soft enough to be cut with little force, and a bar of tin can be bent by hand with little effort. When bent, the so-called "tin cry" can be heard as a result of twinning in tin crystals.

Tin

Droplet of solidified molten tin

Ceremonial giant bronze dirk of the Plougrescant-Ommerschans type, Plougrescant, France, 1500–1300 BC

Sample of cassiterite, the main ore of tin