Wrought iron is an iron alloy with a very low carbon content in contrast to that of cast iron. It is a semi-fused mass of iron with fibrous slag inclusions, which give it a wood-like "grain" that is visible when it is etched, rusted, or bent to failure. Wrought iron is tough, malleable, ductile, corrosion resistant, and easily forge welded, but is more difficult to weld electrically.

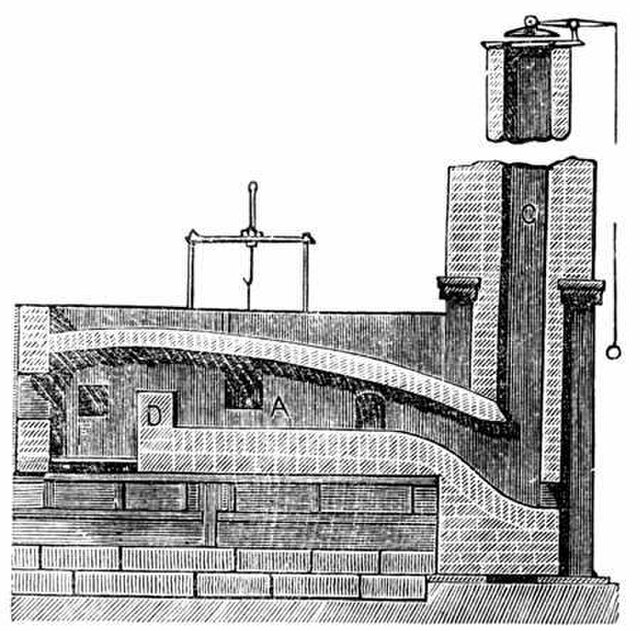

Schematic drawing of a puddling furnace

The microstructure of wrought iron, showing dark slag inclusions in ferrite

Image: Eiffel tower from below

Image: Balcon d'un immeuble parisien

An alloy is a mixture of chemical elements of which at least one is a metal. Unlike chemical compounds with metallic bases, an alloy will retain all the properties of a metal in the resulting material, such as electrical conductivity, ductility, opacity, and luster, but may have properties that differ from those of the pure metals, such as increased strength or hardness. In some cases, an alloy may reduce the overall cost of the material while preserving important properties. In other cases, the mixture imparts synergistic properties to the constituent metal elements such as corrosion resistance or mechanical strength.

From left to right: three alloys (beryllium copper, Inconel, steel) and three pure metals (titanium, aluminum, magnesium)

Liquid bronze, being poured into molds during casting

A brass lamp

A gate valve, made from Inconel