Ampex Data Systems Corporation is an American electronics company founded in 1944 by Alexander M. Poniatoff as a spin-off of Dalmo-Victor. The name AMPEX is a portmanteau, created by its founder, which stands for Alexander M. Poniatoff Excellence. Ampex operates as Ampex Data Systems Corporation, a subsidiary of Delta Information Systems, and consists of two business units. The Silicon Valley unit, known internally as Ampex Data Systems (ADS), manufactures digital data storage systems capable of functioning in harsh environments. The Colorado Springs, Colorado, unit, referred to as Ampex Intelligent Systems (AIS), serves as a laboratory and hub for the company's line of industrial control systems, cyber security products and services and its artificial intelligence/machine learning technology.

Former Ampex headquarters on Broadway in Redwood City, California

Ampex 601 playing a recording of "Les Paul's New Sound, Vol. II". Made in Redwood City, California, c. 1956.

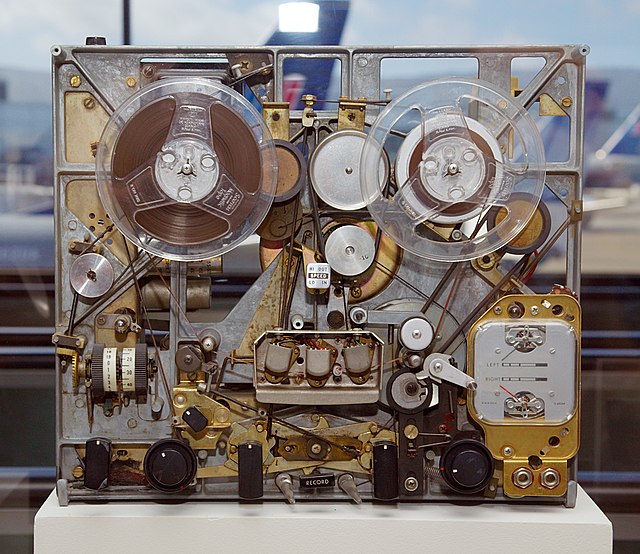

Internals of Ampex Fine Line F-44, a 3-head Ampex home-use audio tape recorder, c. 1965

AMPEX model 300 half-inch three-track recorder

Reel-to-reel audio tape recording

Reel-to-reel audio tape recording, also called open-reel recording, is magnetic tape audio recording in which the recording tape is spooled between reels. To prepare for use, the supply reel containing the tape is placed on a spindle or hub. The end of the tape is manually pulled from the reel, threaded through mechanical guides and over a tape head assembly, and attached by friction to the hub of the second, initially empty takeup reel. Reel-to-reel systems use tape that is 1⁄4, 1⁄2, 1, or 2 inches wide, which normally moves at 3+3⁄4, 7+1⁄2, 15 or 30 inches per second. Domestic consumer machines almost always used 1⁄4 inch (6.35 mm) or narrower tape and many offered slower speeds such as 1+7⁄8 inches per second (4.762 cm/s). All standard tape speeds are derived as a binary submultiple of 30 inches per second.

A reel-to-reel tape recorder (Sony TC-630), typical of a 1970s audiophile device.

Magnetophon from a German radio station in World War II.

Unitra ZK-147, a vintage Polish-made reel-to-reel tape recorder

7-inch reel of 1⁄4-inch-wide (6.4 mm) recording tape, typical of non-professional use in the 1950s–70s. Studios generally used 101⁄2 inch reels on PET film backings.