Córdoba, or sometimes Cordova, is a city in Andalusia, Spain, and the capital of the province of Córdoba. It is the third most populated municipality in Andalusia.

Image: Córdoba aerial 2

Image: CORDOBA(Mezquita) (cropped)

Image: Cordoba 28 (48026695918)

Reconstruction of the Roman temple of Córdoba

Andalusia is the southernmost autonomous community in Peninsular Spain. Andalusia is located in the south of the Iberian Peninsula, in southwestern Europe. It is the most populous and the second-largest autonomous community in the country. It is officially recognised as a historical nationality and a national reality. The territory is divided into eight provinces: Almería, Cádiz, Córdoba, Granada, Huelva, Jaén, Málaga, and Seville. Its capital city is Seville. The seat of the High Court of Justice of Andalusia is located in the city of Granada.

Portrait of Blas Infante, executed in azulejos, located on the avenue in Jerez de la Frontera named in his honour.

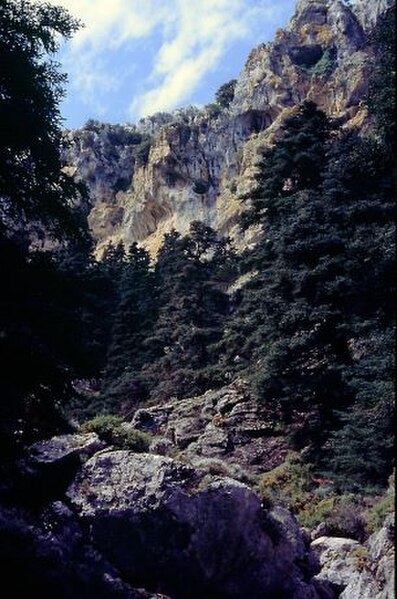

Andalusian firs, Sierra de las Nieves

Mulhacén peak is the highest point of continental Europe outside the Caucasus Mountains and the Alps. It is part of the Sierra Nevada range.

The Guadalquivir as it passes through Córdoba.