The flying shuttle is a type of weaving shuttle. It was a pivotal advancement in the mechanisation of weaving during the initial stages of the Industrial Revolution, and facilitated the weaving of considerably broader fabrics, enabling the production of wider textiles. Moreover, its mechanical implementation paved the way for the introduction of automatic machine looms.

From above, showing conical pirn, and end-feed mechanism (the yarn slips off the end of the pirn, which need not rotate).

Flying shuttle in the shuttle race

Holding the reed beater bar in the left hand and the (stick-mounted) string tugged to return the flying shuttle in the right hand. See video below.

Narrow tanmono loom with an obvious shuttle race on a top-mounted beater bar. Late 1800s Japan.

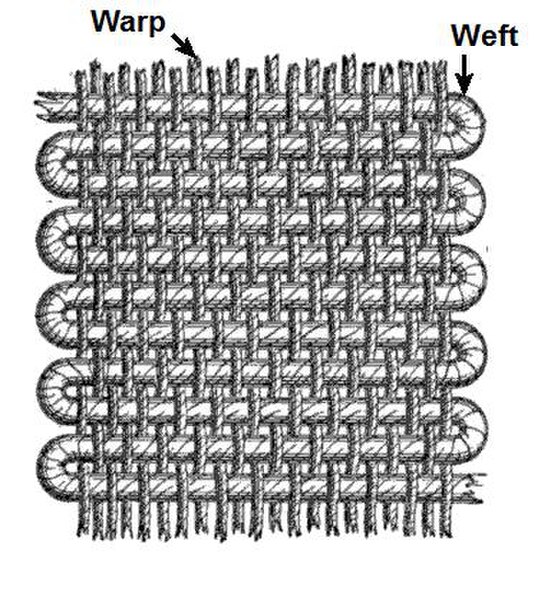

Weaving is a method of textile production in which two distinct sets of yarns or threads are interlaced at right angles to form a fabric or cloth. Other methods are knitting, crocheting, felting, and braiding or plaiting. The longitudinal threads are called the warp and the lateral threads are the weft, woof, or filling. The method in which these threads are interwoven affects the characteristics of the cloth.

Cloth is usually woven on a loom, a device that holds the warp threads in place while filling threads are woven through them. A fabric band that meets this definition of cloth can also be made using other methods, including tablet weaving, back strap loom, or other techniques that can be done without looms.

Warp and weft in plain weaving

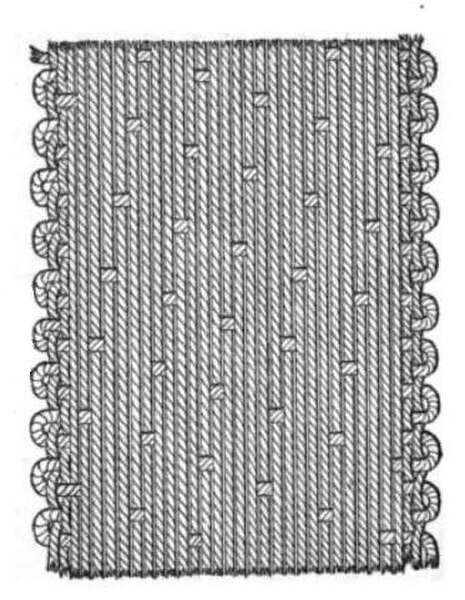

A satin weave, common for silk, in which each warp thread floats over 16 weft threads

A Bangladesh Ansar officer weaving on duty.

Weaving pattern cards used by Skye Weavers, Isle of Skye, Scotland