A loading gauge is a diagram or physical structure that defines the maximum height and width dimensions in railway vehicles and their loads. Their purpose is to ensure that rail vehicles can pass safely through tunnels and under bridges, and keep clear of platforms, trackside buildings and structures. Classification systems vary between different countries, and gauges may vary across a network, even if the track gauge is uniform.

The clearance space between a train and the tunnel is often small. Pictured is a London Underground Northern line 1995 Stock train emerging from the tunnel north of Hendon Central station.

The London Underground utilises differing loading gauges: a Metropolitan line A Stock sub-surface train (left) passes a Piccadilly line 1973 Stock tube train (right).

Zürich – Lucerne IC 2000 double-decker Intercity train

Double-decker carriage as used on French TGV railways

In rail transport, track gauge is the distance between the two rails of a railway track. All vehicles on a rail network must have wheelsets that are compatible with the track gauge. Since many different track gauges exist worldwide, gauge differences often present a barrier to wider operation on railway networks.

Fish-belly cast-iron rails from the Cromford and High Peak Railway

An early Stephenson locomotive

Triple gauge, from left: 1,435 mm (4 ft 8+1⁄2 in), 1,000 mm (3 ft 3+3⁄8 in), and 600 mm (1 ft 11+5⁄8 in), on display at the China Railway Museum in Beijing

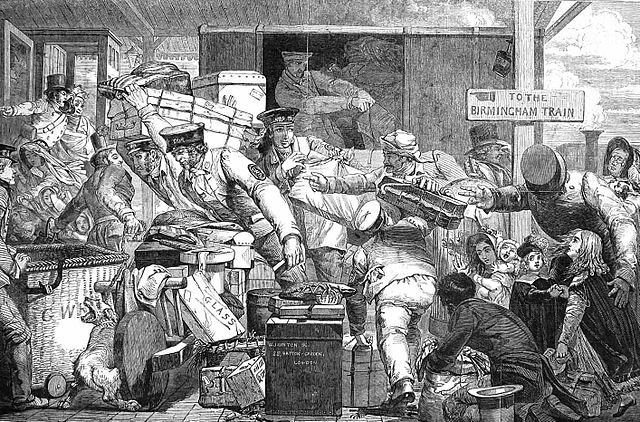

A cartoon depicting the horrors of goods transfer at the break of gauge at Gloucester in 1843