Surface-mount technology (SMT), originally called planar mounting, is a method in which the electrical components are mounted directly onto the surface of a printed circuit board (PCB). An electrical component mounted in this manner is referred to as a surface-mount device (SMD). In industry, this approach has largely replaced the through-hole technology construction method of fitting components, in large part because SMT allows for increased manufacturing automation which reduces cost and improves quality. It also allows for more components to fit on a given area of substrate. Both technologies can be used on the same board, with the through-hole technology often used for components not suitable for surface mounting such as large transformers and heat-sinked power semiconductors.

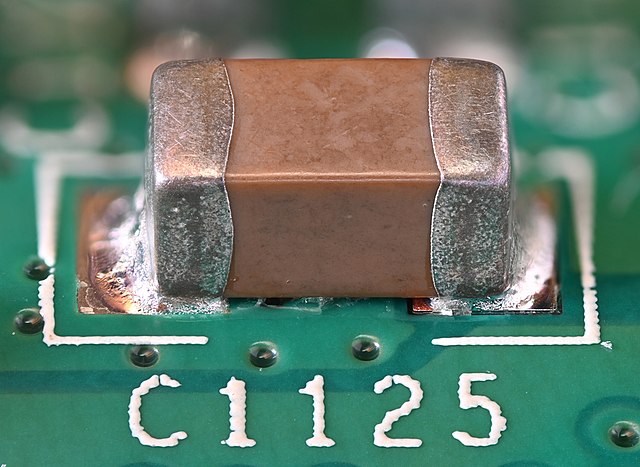

Surface-mount components on a USB flash drive's circuit board. The small rectangular chips with numbers are resistors, while the unmarked small rectangular chips are capacitors. The capacitors and resistors pictured are 0603 (1608 metric) package sizes, along with a very slightly larger 0805 (2012 metric) ferrite bead.

Surface-mount capacitor

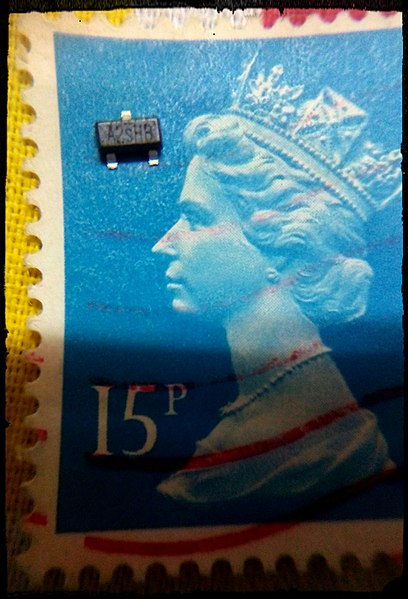

A MOSFET transistor, placed upon a British postage stamp for size comparison.

Assembly line with pick-and-place machines

A printed circuit board (PCB), also called printed wiring board (PWB), is a medium used to connect or "wire" components to one another in a circuit. It takes the form of a laminated sandwich structure of conductive and insulating layers: each of the conductive layers is designed with a pattern of traces, planes and other features etched from one or more sheet layers of copper laminated onto and/or between sheet layers of a non-conductive substrate. Electrical components may be fixed to conductive pads on the outer layers in the shape designed to accept the component's terminals, generally by means of soldering, to both electrically connect and mechanically fasten them to it. Another manufacturing process adds vias, plated-through holes that allow interconnections between layers.

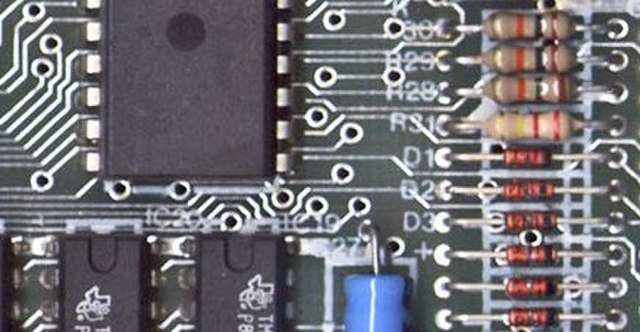

Printed circuit board of a DVD player

Part of a 1984 Sinclair ZX Spectrum computer board, a printed circuit board, showing the conductive traces, the through-hole paths to the other surface, and some electronic components mounted using through-hole mounting

Proximity fuze Mark 53 production line 1944

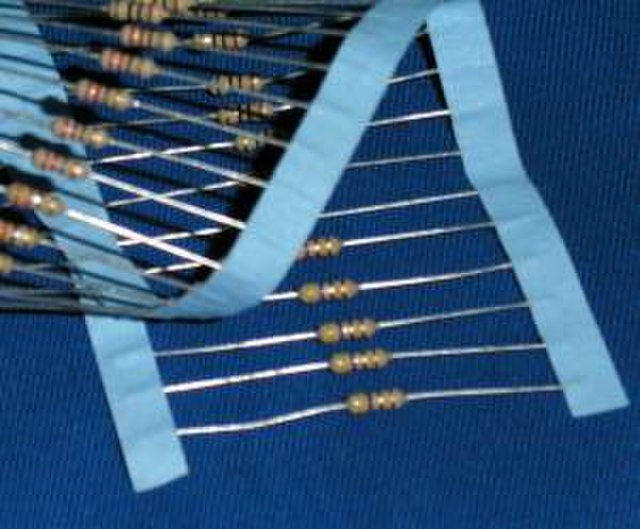

Through-hole (leaded) resistors