A tuning fork is an acoustic resonator in the form of a two-pronged fork with the prongs (tines) formed from a U-shaped bar of elastic metal. It resonates at a specific constant pitch when set vibrating by striking it against a surface or with an object, and emits a pure musical tone once the high overtones fade out. A tuning fork's pitch depends on the length and mass of the two prongs. They are traditional sources of standard pitch for tuning musical instruments.

Tuning fork by John Walker stamped with note (E) and frequency in hertz (659)

Quartz crystal resonator from a modern quartz watch, formed in the shape of a tuning fork. It vibrates at 32,768 Hz, in the ultrasonic range.

A Bulova Accutron watch from the 1960s, which uses a steel tuning fork (visible in center) vibrating at 360 Hz.

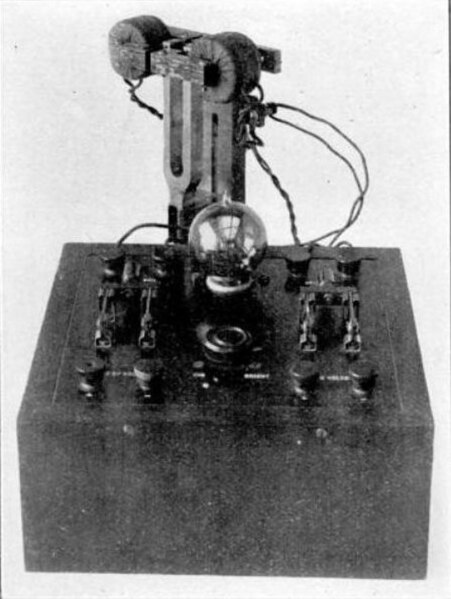

1 kHz tuning fork vacuum tube oscillator used by the U.S. National Bureau of Standards (now NIST) in 1927 as a frequency standard.

A resonator is a device or system that exhibits resonance or resonant behavior. That is, it naturally oscillates with greater amplitude at some frequencies, called resonant frequencies, than at other frequencies. The oscillations in a resonator can be either electromagnetic or mechanical. Resonators are used to either generate waves of specific frequencies or to select specific frequencies from a signal. Musical instruments use acoustic resonators that produce sound waves of specific tones. Another example is quartz crystals used in electronic devices such as radio transmitters and quartz watches to produce oscillations of very precise frequency.

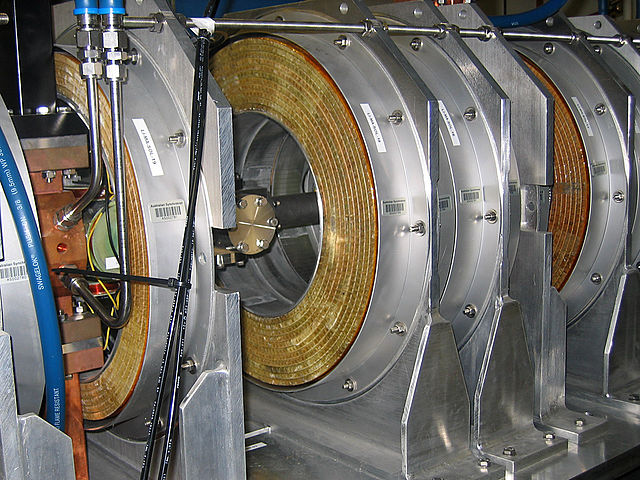

RF cavities in the linac of the Australian Synchrotron are used to accelerate and bunch beams of electrons; the linac is the tube passing through the middle of the cavity.

A sport motorcycle, equipped with exhaust resonator, designed for performance

A Dobro-style resonator guitar